Elasticity is our trump.

We are in constant contact with our client and we dynamically react to altering product expectations.

Need

PRO-ASSEM comes ahead of the client’s needs, to face together the requirements of modern industrial market. PRO-ASSEM’s activity distinguishes itself in reliability, elasticity and complete involvement in fulfilling customer’s expectations.

We achieve professional and coherent with the specification realisation of the acquired contracts by basing on the knowledge and experience of well qualified engineering team, who watches over all of the production phases, since conceptional one till startup of the finished machine at the customer’s facility.

Conception

After coordination with the client's requirements, our team starts the conceptual phase of the work.

During this production stage the ideas are transformed into the actual technical solutions used in created machine. Sketches and schematics are drawn, initial calculation are made, which are based on years of tested solutions, all to ensure optimal, ergonomic and easy in exploitation construction of the machine.

Design

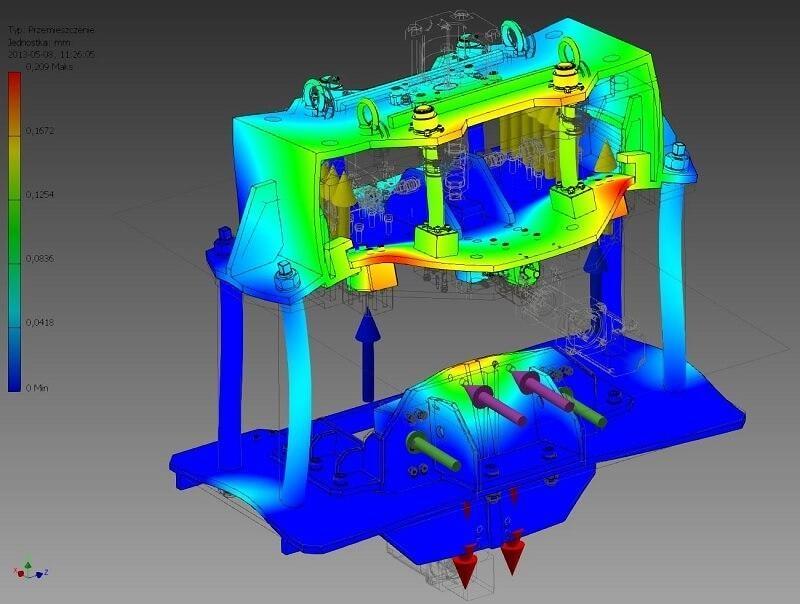

After finishing the conceptual phase, the next step is starting the design stage.

PRO-ASSEM designs it’s projects using modern CAD software of the leading producer. Created 3D models allows for the verification of design assumptions even on the early stage of their development, as well as are a convenient way of data exchange and presenting work progress for both client and producer. What is more, usage of the project data management system guarantee efficient and transparent construction process, even while working with complex applications.

Manufacturing

Closed design phase means transition into the manufacturing stage of the details, which of the machine consists of.

PRO-ASSEM is has its own machine park at disposal, equipped with among others numerically controlled machines, which operate using CAM software. That allows for fast and precise manufacturing of the complex geometry parts. Throughout years of existing on the market, our company gained renown and trust among number of subcontractors and tradesmans, what allows us for fast acquisition of top quality trade elements and blanks.

Start up

The final stages of the works related to realisation of the project are: components assembly, running tests and start up the machine at the customer’s facility.

PRO-ASSEM providing complex services has at its disposal area destined for assembly of earlier manufactured parts and purchased trade elements in complete machine, which under surveliance of members of the automatics department goes through demanding series of tests, which purpose is to verify in practise the design assumptions. The product inspected in that manner later is transported to the recipient, where well qualified PRO-ASSEM crew execute the machine start up process, to ensure proper work of the device, thereby the customer satisfaction, which is the most important for us.

We provide a professional service such as bespoke machine building. We are committed to the satisfaction of all customers, so we rise to the challenge by offering the highest quality equipment. It is not always possible to find the ideal equipment for a particular industry - sometimes it proves necessary to customize it. In such a situation, our work is invaluable. We are able to design machines from scratch and then build them on a special order. All equipment that comes out from under our hands is distinguished by high quality workmanship, durability and functionality. We also do not forget about the aesthetics of the equipment. Trust us and see for yourself the many advantages of custom-built machines.

Outsourcing machine building is very beneficial, regardless of the industry in which the company operates. Experience and knowledge allow us to construct a variety of equipment to suit many needs. The main benefit of ordering equipment is the individual approach - our employees, accepting the order, focus exclusively on it, doing everything to satisfy the customer with their work. Of course, all ideas are agreed with the customer and executed with his approval.

On demand, we are able to carry out even the most complex and advanced projects. Such a service is also associated with great savings, since the company gains fully automated equipment. Some of them are even able to replace people and work without any operator. Custom-built machines are characterized not only by high quality, but also by safety. We control their creation at every stage, which increases confidence that all components are in working order and ready for operation.